Two points are above the upper control limit. Nach Jahn 20 berechnet sich OEG wird dort SKG genannt über.

Control Chart Limits Ucl Lcl How To Calculate Control Limits

1 F z n z n z z n OEG mit z Anzahl Merkmale Prozessvariable bzw.

Upper control limit berechnen. If the specifications either upper or lower are inside of the of the control limits boundaries then the. Conversely consider a call center where calls must be answered within 30 seconds. Upper age limit n.

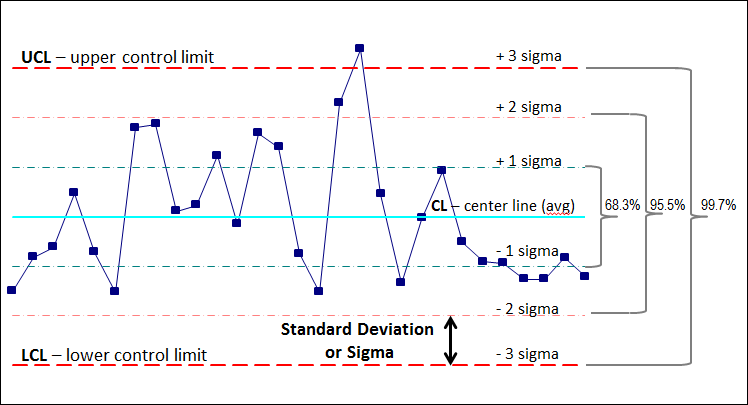

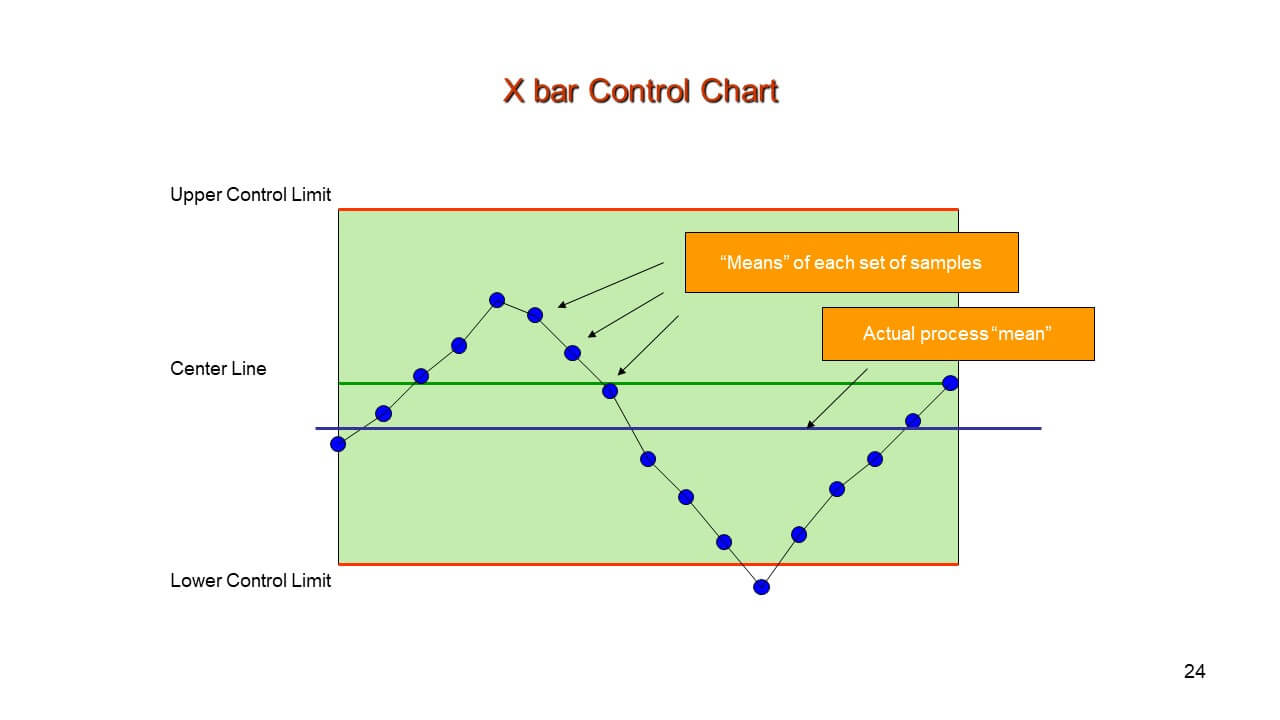

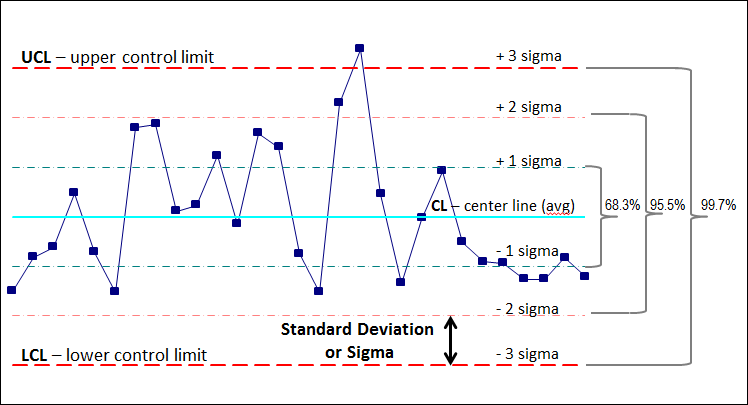

The top dashed line is the upper control limit UCL. We tried to find some amazing references about how to calculate upper and lower control limits in excel sample for you. It is placed 3 sigma of the data being plotted away from the average line.

Merkmale n Anzahl Messungen 20 40 60 80 100 120 140 Einzelmesswerte 20 40 60 80 100 120 140 160 20 40 60 80 100 120 140 T² Hotelling 0 5 10 15 20 T² Mittel OEG x1 x2 x3 x4x5. It is also used to define the upper limit of the common. How are specification limits different from control limits.

The quality analysts set a lower specification limit but do not set an upper specification limit because purer is better. Upper confidence limit n. The upper control limits UCL and lower control limits LCL for the Mab control antigen plus Mab in the absence of test sera are between OD values 04 and 14.

They are what is acceptable to the customer. The upper and lower control limits are based on the random variation in the process. T 1 the upper control limit in time period t 1.

The upper control limit is used to mark the point beyond which a sample value is considered a special cause of variation. Value in the X-bar chart bigger than 3 sigma the u sual upper control limit for a X-bar chart. This is the same principle applied in case of calculating control limits.

The highest limit a customer would accept. 3 Schritt 3 Wählen Sie im Popup-Fenster Limit suchen. Dargestellt Englisch UCL upper control limit.

If a value is bigger than 3 it is equal to a. 15 rows UCL Upper Control Limit as it applies to X Bar mean and R Bar. Zsubt the center line Eq.

In some cases UCL is higher than USL. UCL Average 314Median Range LCL Average - 314Median Range I was told that this is the correct way to calculate the UCL and LCL. The control limits as pictured in the graph might be 0001 probability limits.

Upper limit of range n. I would like to make a histogram using the SPC Histogram visualization with some dynamic upperlower limits target according to my products it will change. In these cases process should be maintained between USL and LSL.

If so and if chance causes alone were present the probability of a point falling above the upper limit would be one out of a thousand and similarly a point falling below the lower limit would be one out of a thousand. In this case only an upper specification is relevant because the quicker a call is answered the better. We would be searching for an assignable cause if a point would fall outside these.

SPC Histogram 6 Sigma graph with lowerupper limits target. LCL Mean 3 x Standard deviation. We hope you can find what you need here.

For example this Xbar chart displays the length of manufactured camshafts over time. We always attempt to reveal a picture with high resolution or with perfect. Cpk 100 means that 2 700 PPM 027 of the manufactured parts are out of tolerance while Cpk 133 means that 63 PPM 00063 are rejects.

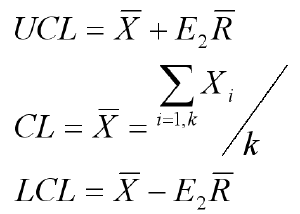

Das upper limit of normal. By default Minitabs control limits are displayed 3 standard deviations above and below the center line. Calculate control limits using following formula.

Er markiert die obere Begrenzung des Referenzbereichs. Specification limits are different from control limits as they are not calculated using means and standard deviations but are instead values determined by the designers via the customer to be within acceptable quality boundaries. Spreadsheet March 17 2017.

In case of plotting real-time process variable x assuming x follows a normal distribution and assuming the UCL and LCL cover 997 of the normal operating data the UCL and LCL are defined as. A customer would wait in line at a drive through 7 minutes before being dissatisfied. Schritt 1 Geben Sie Ihr Limit-Problem in das Eingabefeld ein.

Specification limits are different than control limits which are calculated according to the control chart you are using. For your convenience I attached the excel file with my calculation. Upper control limit UCL and lower control limit LCL are calculated by specifying the level of significance α.

Als upper limit of normal kurz ULN bezeichnet man den als oberen Grenzwert definierten Wert einer Standardnormalverteilung. LCLsubt 1 the lower control limit in time period t 1. 2 Schritt 2 Drücken Sie die Eingabetaste auf der Tastatur oder auf dem Pfeil rechts neben dem Eingabefeld.

The upper control limit is calculated from the data that is plotted on the control chart. The lowest limit a customer. Please let me know what is your opinion in this case.

Upper limit temperature n. In a quality control context PPM stands for the number of parts per million cf. Percent that lie outside the tolerance limits.

Permissible upper limit n. Der Begriff wird in der Medizin zum Beispiel im Zusammenhang mit der Spirometrie verwendet. It was coming from reputable online resource and that we like it.

Viele übersetzte Beispielsätze mit upper control limit Deutsch-Englisch Wörterbuch und Suchmaschine für Millionen von Deutsch-Übersetzungen. Intelligent monitoring and statistical process control of surface roughness on CNC turning process.

Lower limit of normal. UCL Mean 3 x Standard deviation.

Kontrollkarte 101 Definition Zweck Und Vorgehensweise

Spc Calculating Upper Lower Control Limits Youtube

Control Chart Limits Ucl Lcl How To Calculate Control Limits